FactoryTalk Batch 配方编辑器(Batch Recipe Editor)用于创建和配置主配方。 FactoryTalk Batch 配方编辑器可以使用表格tables、顺序功能图sequential function charts 或两者,以图形方式将程序信息组织到单元程序unit procedures、操作operations和阶段phases中。 配方的制定者可以使用编辑器用来创建或编辑配方(步骤序列)和公式值(参数、设定点值等)。

所有配方均使用 ISA S88.01 标准进行配置和显示。

打开Recipe Editor

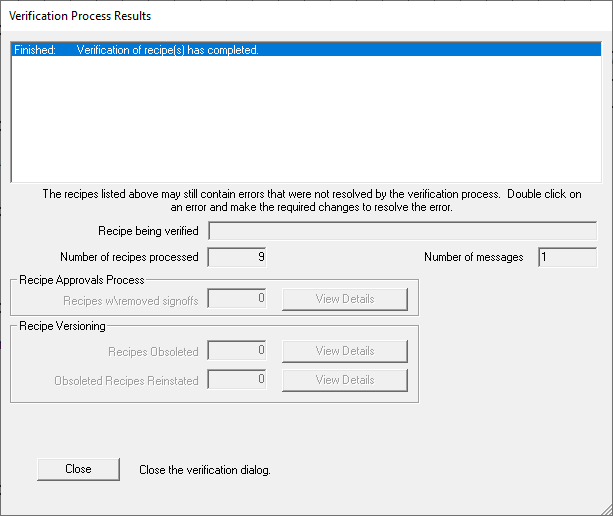

- 开始菜单 > Rockwell Software > Recipe Editor,点击之后会显示一个空的Recipe Editor. 如果提示验证,点击Yes去验证该区域模型里所有的配方。

-

验证完成之后点Close关闭验证窗口。

主窗体布局如下:

• 程序视图窗格

Procedure View pane位于编辑器的左侧,包含当前配方组件的分层列表。 从列表中选择一个组件会在“配方构建”窗格Recipe Construction pane中显示相应的步骤。

• 配方构建窗格Recipe Construction pane位于编辑器的右侧,用于编辑主配方。 可以使用顺序功能图 (SFC) 或表格来编辑和查看配方结构。

打开一个配方

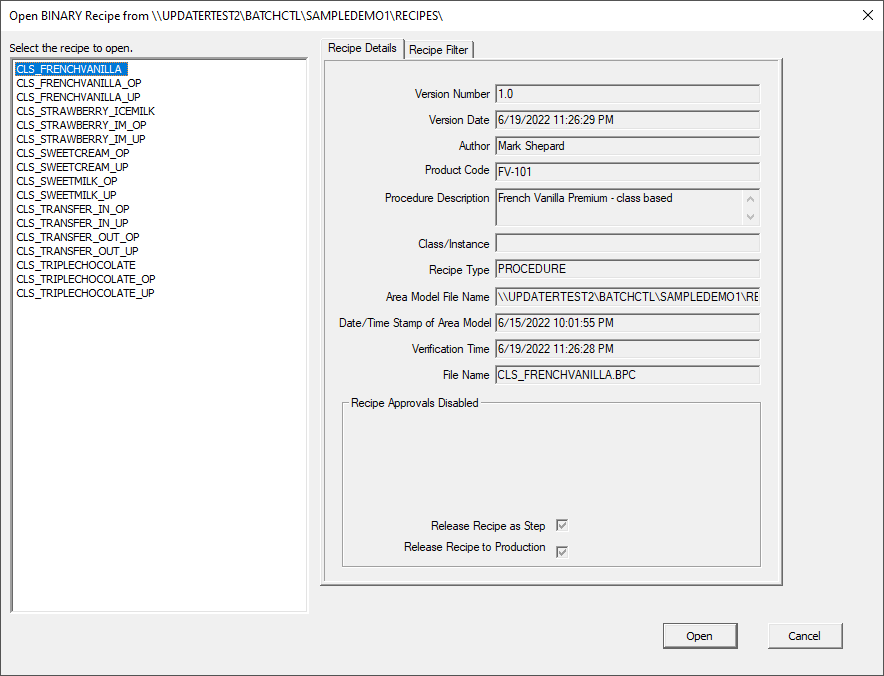

- 从文件菜单中,选择

Open Top Level。 打开 [类型] 配方对话框。 类型是 BINARY。 (配方也可以存储为XML格式或者RDB格式。) - 从选择要打开的配方列表中,选择

CLS_FRENCHVANILLA。 在右侧展示配方有关的信息。有两个复选框Release Recipe as Step和Release Recipe to Production。

- 点击Open.

打开配方CLS_FRENCHVANILLA后,左侧过程视图显示的是配方结构,右侧显示的是配方结构的SFC版本。

添加顺序步骤

- 选择工具栏中的指针图标后,点击左侧过程视图中的

CLS_SWEETCREAM_UP:1单元过程。将显示CLS_SWEETCREAM_OP:1操作。 - 点击

CLS_SWEETCREAM_OP:1操作。显示该操作中的所有步骤。 - 选择OP底部的 ADD_MILK:1 STATE = COMPLETE 转换(transition)。

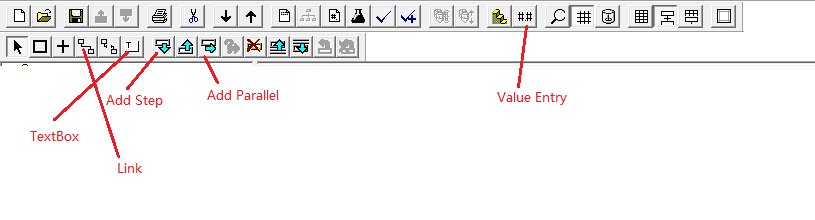

- 在配方构建工具箱中选择添加步骤(Add Step)。

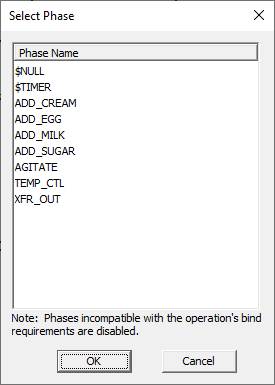

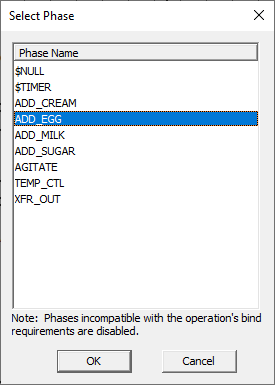

新的步骤和转换将添加到所选转换下方,并打开“选择阶段”对话框。

- 选择 XFR_OUT,然后选择 OK。新步骤定义为 XFR_OUT:1,步骤下方的转换定义为 XFR_OUT:1.STATE = COMPLETE。

添加并行步骤

- 仍然在

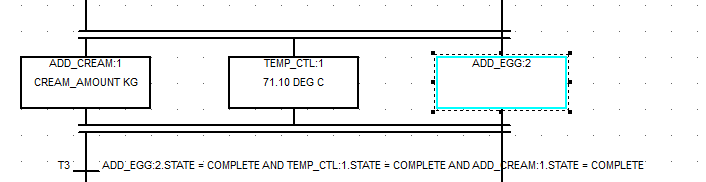

CLS_SWEETCREAM_OP:1操作, 选择步骤TEMP_CTL:1 - 选择“添加并行”。将与所选步骤并行添加一个新步骤(Add Parallel),并打开“选择阶段”对话框。

-

选择 ADD_EGG,然后选择“确定”。

新的步骤现在定义为

ADD_EGG:2,并且该步骤下方的转换自动重新定义为ADD_EGG:2.STATE = COMPLETE AND TEMP_CTL:1.STATE = COMPLETE AND ADD_CREAM:1.STATE = COMPLETE,以反映新的并行结构。

分配步骤公式值

- 仍在

CLS_SWEETCREAM_OP:1中,选择ADD_EGG:2步骤。 - 在工具栏中选择

值输入(Value Entry)。打开参数对话框,列出与该步骤相关的参数。这里唯一的参数是ADD_AMOUNT。 -

在 值(value) 框中键入 100,然后勾选 “显示(Display)”,这样值就会显示在 SFC 上。

- 选择 “确定” 返回到 FactoryTalk Batch 配方编辑器窗口。接下来,修改 TEMP_CTL:1 的参数,以便操作员可以在批次运行时输入数值。

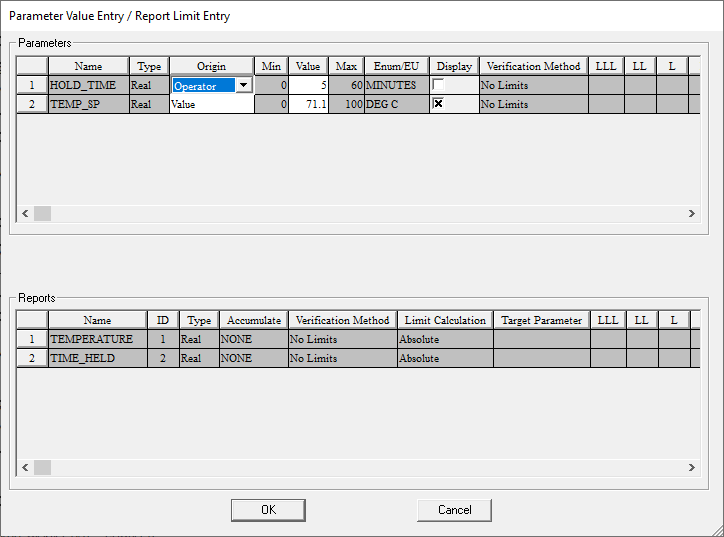

- 选择 TEMP_CTL:1 步骤,然后选择 “值输入”。此时将打开 “参数值输入 / 报告限值输入” 对话框,其中列出了与该步骤相关的参数。共有两个参数:HOLD_TIME(保持时间)和 TEMP_SP(温度设定点)。您希望让操作员决定将混合物保持多长时间。

- 对于 HOLD_TIME 参数,从 “来源” 列表中选择 “Operator(操作员)”,以指示在运行配方时由操作员输入该数值。

- 点击OK返回FactoryTalk Batch Recipe 编辑窗口

添加配方注释

配方注释功能可让您创建和编辑注释,以便在设计阶段和运行阶段查看。利用此功能,可将重要信息插入配方中,并将其与特定步骤、转换或整个配方关联。

- 仍处于 CLS_SWEETCREAM_OP:1 操作界面时,选择 文本框工具(Text Box Tool)。此时光标将变为文本编辑工具样式。

- 将光标移至 AGITATE:1 步骤的右侧并点击,SFC 图中将出现一个标有 C1 的文本框。

- 选择 链接工具(Link),此时光标变为带加号(+)的样式,将其移回 C1 文本框。

- 在文本框内任意位置点击并按住鼠标左键,将光标拖至 AGITATE:1 步骤。此时文本框下半部分将显示 AGITATE:1,表明该文本框已与此步骤关联。

- 选择 选择工具(Selection Tool),双击文本框内部,输入以下内容:如果混合物开始分离,将搅拌速度降至 20 RPM。

添加连续循环

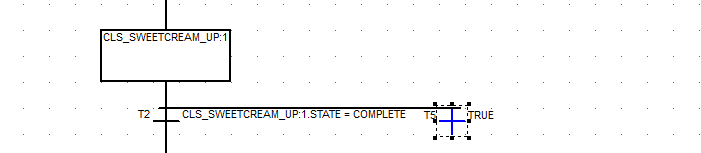

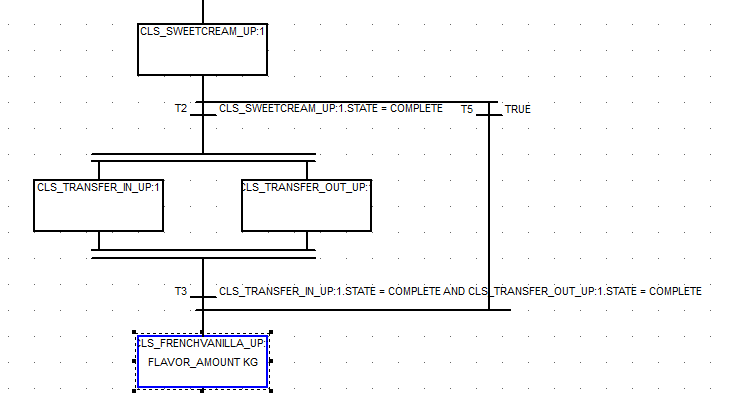

- 在工具栏上选择 “向上” 两次,以导航至 CLS_SWEETCREAM_UP:1 单元程序。

- 选择 转换工具。将指针放置在已标记为 CLS_SWEETCREAM_UP:1.STATE = COMPLETE 的现有转换右侧,然后点击添加一个未定义的转换。

- 选择 链接工具 按钮。

- 从标记为 CLS_SWEETCREAM_UP:1 的步骤开始,拖动指针至新创建的 TRUE 转换,释放鼠标以添加链接。

- 从 TRUE 转换拖动指针至单元程序的最后一步(CLS_FRENCHVANILLA_UP:1),从而完成循环结构。

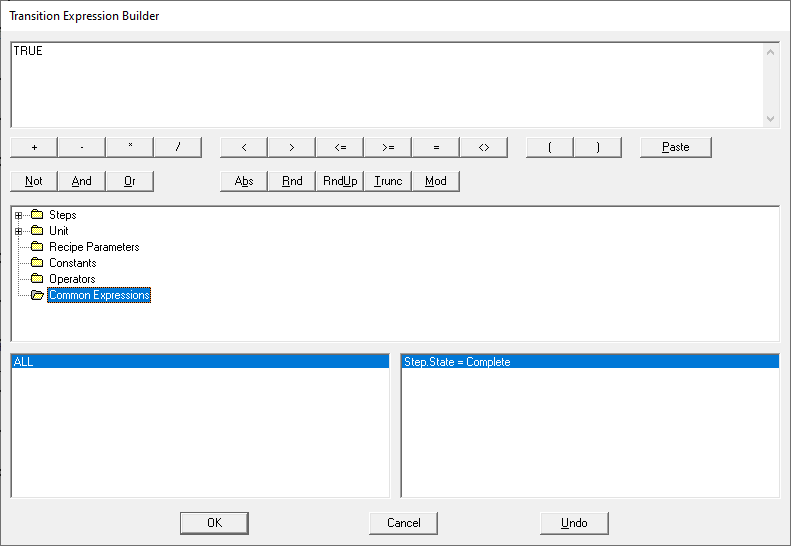

- 选择 选择工具 按钮,然后双击新创建的 TRUE 转换。

- 选择 常用表达式 文件夹。

- 双击 Step.State = Complete。

- 在对话框的上部,高亮显示表达式中的等号(=),然后选择 大于或小于 按钮。此时转换条件应变为 CLS_SWEETCREAM_UP:1.STATE <> COMPLETE。此转换确保 CLS_SWEETCREAM_UP:1 操作将持续运行,直到达到 COMPLETE 状态。

- 选择 确定。

删除操作

从示例操作中删除顺序步骤:

- 仍处于 CLS_SWEETCREAM_OP:1 操作时,选择 XFR_OUT:1 步骤。

- 选择 删除步骤(Remove Step) 按钮。此时 XFR_OUT:1 步骤及其链接和后续转换将被移除,SFC(顺序功能图)会自动重新排列以适应删除的步骤。

从示例操作中删除并行步骤:

- 仍处于 CLS_SWEETCREAM_OP:1 操作时,选择 ADD_EGG:2 并行步骤。

- 选择 删除步骤 工具。此时 ADD_EGG:2 并行步骤及其链接将被移除,后续转换会重新配置,SFC 会自动调整布局以适配删除的步骤。

验证配方

- 选择 验证(Verify)按钮,系统将打开 “验证过程结果” 对话框。正常结果应显示:CLS_FRENCHVANILLA » 配方验证已完成。

- 选择 关闭(Close)按钮。